FORUM CTRLX AUTOMATION

ctrlX World Partner Apps for ctrlX AUTOMATION

Dear Community User! We are updating our platform to a new

system.

Read more: Important

information on the platform change.

Torque/force scaling

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Torque/force scaling

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

01-29-2024 06:55 PM

According to the help file, the torque/force scaling is performed against a reference value calculated using the formula:

Reference value = S-0-0111*P-0-0051*cooling factor type = 27.420*1.97*1= 54.0174

For the motor I am using (MAD100D-0250) this is equal to the continuous torque at standstill i.e. 54 Nm.

While I was running the motor in 'Velocity Control' at roughly 185 RPM and a torque of 1.5 Nm (externally measured using a torque sensor), Indraworks reported an Effective torque/force command value of roughly 170%.

How does 1.5 Nm of torque correspond to an effective request value of 170%?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

02-06-2024 01:20 PM

Please send the drive parameter file (in format "all parameters"). Presumably the scaling is set not correctly.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

02-07-2024 07:59 AM

Hi @Drives_Uwe, the parameter file is attached.

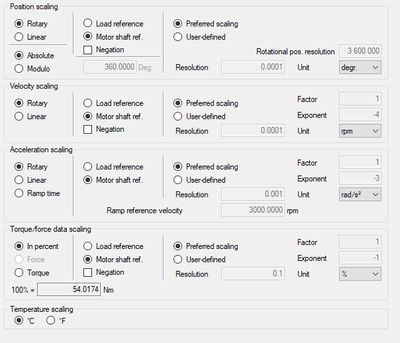

Below is the screenshot of the 'Scaling/Units Extended' tab:

Even when I switch the scaling from 'In percent' to 'Torque', the amount of torque shown does not correlate with the reading of the 'torque sensors' or the torque setpoint on the 'load machine' (data from the 'load machine' and the 'torque sensors' match).

Thanks in advance!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

02-07-2024 09:23 AM - edited 02-07-2024 09:27 AM

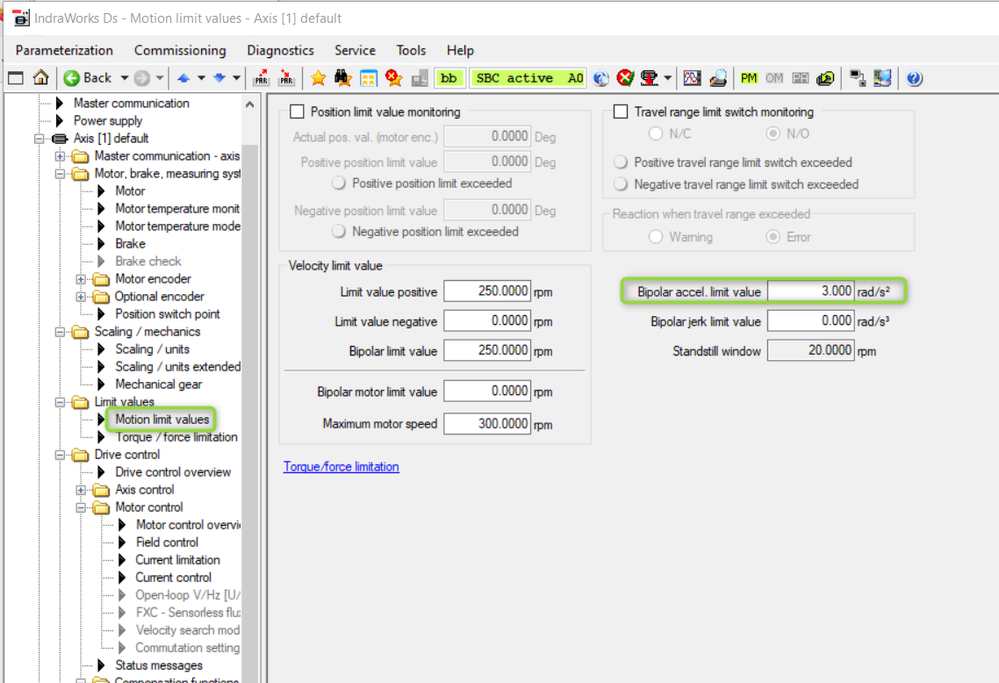

At checking your parameter settings I found one weird input:

Please set the acceleration limit value either to "0" or a reasonable value like 500 to 2000 rad/s^2.

If this doesn´t help, create an oscilloscope reading in the strange situation recording S-0-0040, S-0-0084, P-0-0043, P-0-0044 and P-0-0445 as signals.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

02-12-2024 04:46 PM

I set the value as 500 and did a test run and it did not really help.

Will try setting it as 0 as see what happens. If that doesnt work, I will try to send you an oscilloscope reading of the requested parameters. Thank you for the help!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

02-14-2024 11:26 AM

Hi,

So I ran the test with the Bipolar Acceleration Limit Set to '0', but did not notice any improvements. The parameter file and the scope file is attached. The additional pdf. file shows the speed and torque measurements from the external signal. There is a single stage gear train between the drive motor and load machine with a reduction ratio of '3.3'.

Thank you for your help.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

09-05-2024 10:55 AM

Are there any news? Could you solve your issue?