FORUM CTRLX AUTOMATION

ctrlX World Partner Apps for ctrlX AUTOMATION

Dear Community User! We have started the migration process.

This community is now in READ ONLY mode.

Read more: Important

information on the platform change.

- ctrlX AUTOMATION Community

- Forum ctrlX AUTOMATION

- ctrlX MOTION

- Re: Rotary Axis has large difference when in a kinematic

Rotary Axis has large difference when in a kinematic

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-09-2021 04:59 PM - edited 11-09-2021 04:59 PM

When configuring a kinematic with a rotary axis, the axis will have a 1000 times travel when commanded to a new position with kinematic interface. This is not the case with the axis interface.

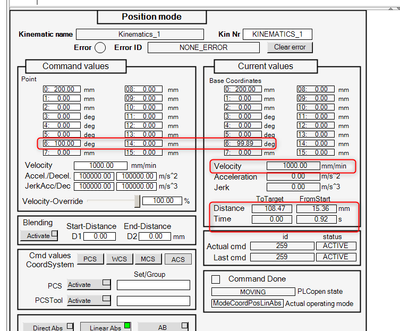

Here is a screen shot of what I am describing. The difference from start to finish should be 0.0108 but it is instead 108. This also has a bad effect on the velocity which is 1000 times too slow.

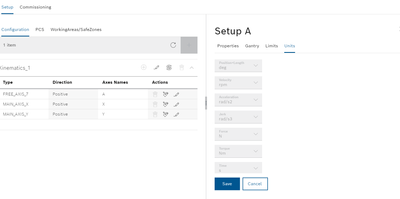

Here is an image of the kinematic configuration

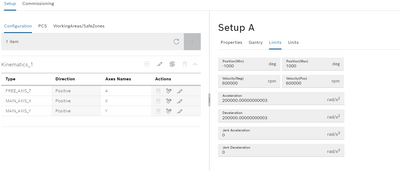

Along with the limits:

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-11-2021 04:39 PM - edited 11-12-2021 01:39 PM

Hello

1. What version do you use? V1.10?

2. Do you see the error at a virtual control with motion axis? Or do you have real drives connected to the motion axis?

Please can you save the configuration and add it to the issue or send me a mail.

Thanks

Jochen

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-12-2021 02:43 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-15-2021 08:51 AM - edited 11-23-2021 12:08 PM

short info: Can reproduce this issue. Have to talk with the development department.

Update 23.22.2021:

Currently we have one set of dynamic limit for commanding the kinematic axis. This set is used for tranlatorc and rotativ axis with a fix calculation factor 1m = 1°. For velocity does it mean 800mm/min = 0,8°/min.

So the behaviour you have seen is (from the current function state) correct.

It is planned to improve this sitaution in the future, unfortunatly earliest end of 2022.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

07-18-2023 06:54 AM - edited 07-18-2023 07:00 AM

Hello,

is it resovled now? which version of ctrlX works is suggested to use.

I am using ctrlX works 1v16, still having the same issue.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

07-21-2023 09:16 AM - edited 07-21-2023 09:20 AM

Solution to get rid of the path factor 1m = 1° will be implemented from version 2.02 on.

Possible workaround:

- Do not command all four axes at the same time (adapting command values 1:1000)

- Command A as single axis movement

- Use "direct absolute" commands where path limits are not considered

- Set up A as linear axis and set total transmission ratio to 1:1 then command 1mm as 1deg

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

07-21-2023 02:54 PM

I have been using this last suggestion for about a year. I set the drive up in such a way that 1mm of travel is 1deg of travel. The axis is setup as linear and so is the drive. I set the modulo for each at 360mm and I convert RPM commands to mm/min commands in the PLC application. For example, 10rpm = 3600 mm/min. This works ok but I still often need to make the commands independently because 3600mm/min on the rotary axis is not fast enough for my other axes which run much faster.