- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

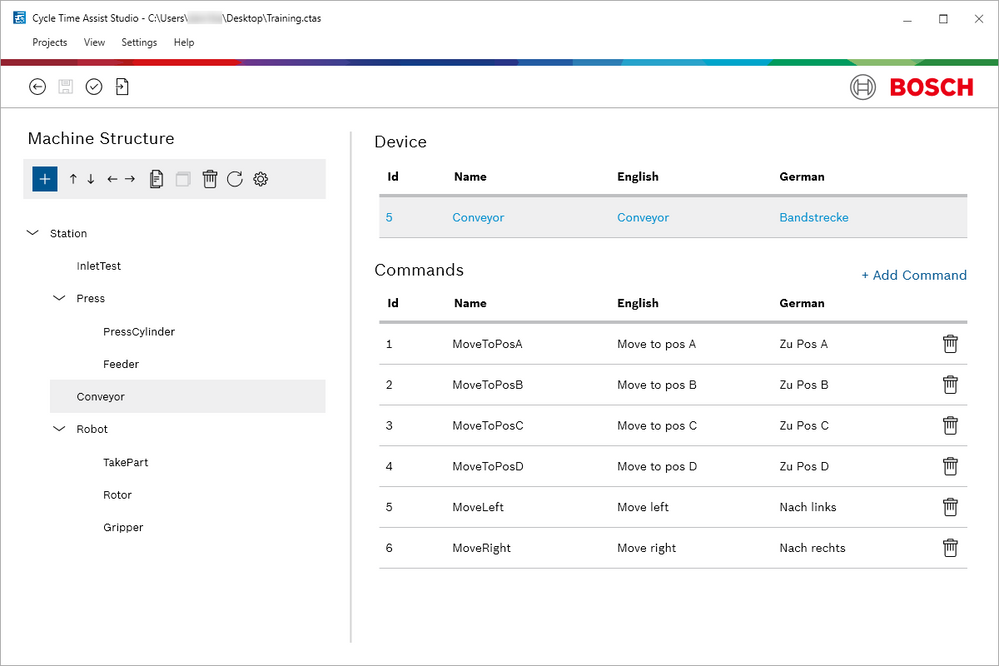

With Cycle Time Assist, you can quickly detect cycle time deviations at the machine in order to take countermeasures at an early stage. Through simple configuration in Cycle Time Assist Studio and the PLC Libs (part of this package), a Cycle Time Assist can visualize and record part cycles for each individual machine. Production managers can see how the cycle times of their machines are doing and keep productivity high. Cycle Time Assist records the part cycle based on data from the PLC and displayed on the machine's user interface.

In addition to the part cycle, Cycle Time Assist can also start a detailed machine recording at adjustable times. All machine activities are recorded - from the movement of individual devices to communication times with other IT systems. Thus, for example, the top 10 view of cycle time eaters can be used to quickly identify those devices that are the cause of a deviating cycle time. In this way, worn or incorrectly functioning devices in a machine can be quickly identified and productivity can be kept high.

The recorded detailed data can be automatically exported to XML or JSON files, which allows easy integration into e.g. cloud-based big-data applications.

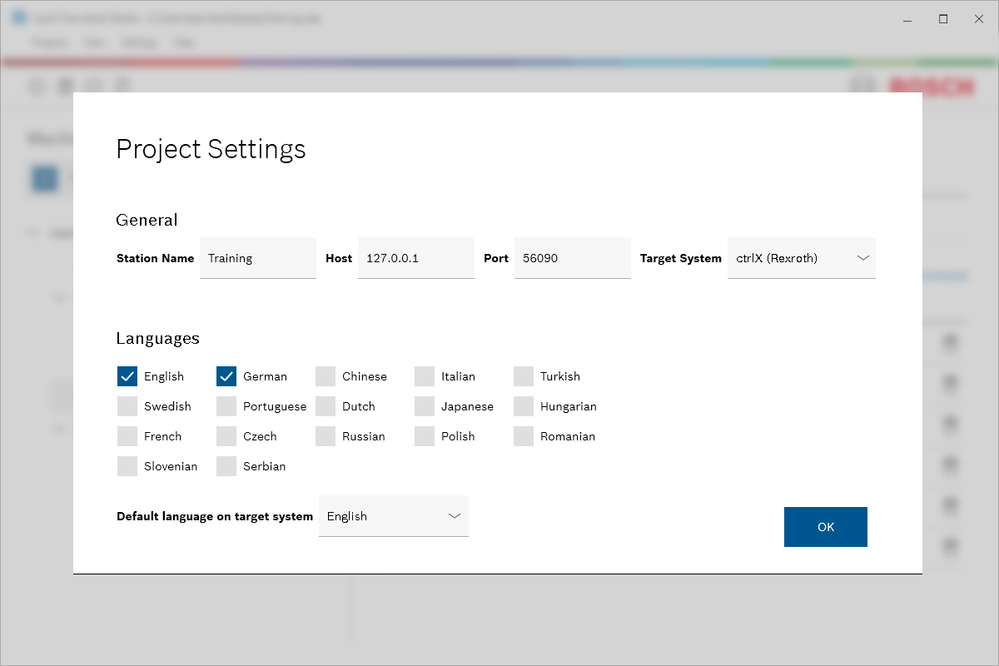

The app is completely web-based and can be displayed on the browser of any device connected to a ctrlX CORE controller. The app is also set up purely via the web interface and can therefore be accessed from any device. We attached great importance to a simple setup, so that the Cycle Time Assist is ready for use in a short time.

Model your Machine Structure

Model your Machine Structure Configure Target PLC

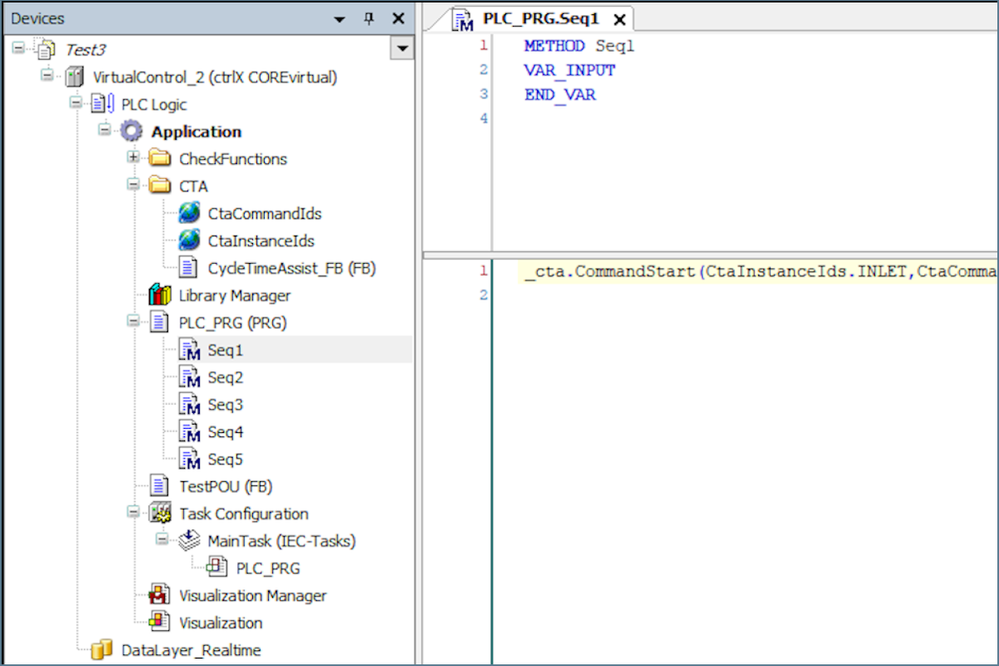

Configure Target PLC Ready to use FBs for the PLC

Ready to use FBs for the PLC

Prerequisites

Documentation

Support

nexeed.helpdesk@bosch.com 1)

Forum Nexeed Automation

Related Links

The Company

Bosch Connected Industry offers software and services for Industry 4.0 in a comprehensive portfolio under the name NEXEED. Based on the needs of its own Bosch plants and warehouses, NEXEED optimizes manufacturing and logistics processes in terms of transparency, agility, costs, quality and time and supports employees in their daily work. With NEXEED, Bosch Connected Industry enables the digitalization of the entire value chain. Employees at locations in Germany, Hungary and China are continuously developing the portfolio. In addition to the interoperable Nexeed Industrial Application System for connected manufacturing, customers also receive individual solutions for specific applications, retrofit solutions for existing plants, as well as a wide range of services such as consulting, technical support, employee qualification, and implementation assistance. For further information: www.bosch-connected-industry.com

1) Note on data protection

The email is sent directly to the partner company! This company is responsible for the processing of the data contained. Please read their data protection information before sending this email! Bosch Rexroth is not responsible for the use of the partner company's support.