- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Requirements

The following prerequesites are necessary to start the procedure:

- Install ctrlX WORKS in its latest version (including ctrlX I/O Engineering).

- Local Network with IPv4 in the same range as the ctrlX CORE

- For connecting to the ctrlX CORE please check the network settings of your PC. The IP address needs to be in the same subnet, e.g. set IP configuration to manual, IP to "192.168.1.42", subnet mask to "255.255.255.0".

- ESI File (EtherCAT Slave Information) for Synapticon drive needs to be downloaded (see below).

Connecting PC to ctrlX CORE

A quick start guide can be found here: Quick start guide ctrlX CORE

Setting up ctrlX CORE Communication

In these steps, the communication between ctrlX CORE (Master) and the Synapticon drive will be established:

-

Open the ctrlX CORE web interface by browsing the IP address of the master. Default IP address: 192.168.1.1.

-

Set up the Master EtherCAT Communication by accessing the EtherCat Master menu.

Access Ether CAT Master menu

-

Press "Add Ether CAT Master".

Add Ether CAT Master

-

Name it and choose the port XF50 (EtherCAT - port) from the dropdown menu.

Choose Port

-

After adding it, please open it by clicking on the newly created item (ethercatmaster here).

Ether CAT Master

-

To add EtherCAT slaves, start the ctrlX I/O Engineering.

Start IO Engineering

-

After opening the I/O Engineering window, build a new project by selecting "New Project" or go to the file menu and choose the New Project option.

ctrlX_Engineering

- Choose "Empty project" and add a name.

Select empty project

-

Add a PLC device by right-clicking on the project and chooe the Add Device option, then select the ctrlX_CORE_IO (ctrlX CORE I/O Configuration) item.

Add Device

- Add the Synapticon ESI file to the repository. Go to the Tool menu, option Device Repository..., under Fieldbus tree, select the EtherCAT Slave. Press the Install button, and select the desired ESI file.

Device Repository

- In case there is no Synapticon ESI file, there are two ways to obtain the ESI file:

- Download it directly from the drive with Synapticon OBLAC software (if available). Select the Device Information menu, and press SAVE ETHERCAT SLAVE INFO.ESI (.xml)

Save Ethercat slave info

-

Request the ESI file from Synapticon Technical Support (support@synapticon.com) with mentioning the drive you have and need the ESI file for.

- Download it directly from the drive with Synapticon OBLAC software (if available). Select the Device Information menu, and press SAVE ETHERCAT SLAVE INFO.ESI (.xml)

-

Add a Fieldbus device by right-clicking the PLC and choose the Add Device option. Then select the EtherCAT Master (ctrlX CORE I/O Configuration) item.

Select EtherCAT Master

-

Adding the Slave (Synapticon Drive).

Connect the Synapticon Drive to the ctrlX CORE through the XF50 port physically, and power on the drive. Add the Slave by right-clicking on the Fieldbus and choosing the Scan Device option. The drives will appear on Control Side. Move them to Project Side with the buttons and press Apply. -

Save the project.

-

To see the real-time data from the slave and the PDO/SDO, select the slave on the Device (1) Menu, open the CoE tab (2), press Transfer Fieldbus Configuration (3), press Show Online Data (4), observe the Online status will appear (5), and select Description from slave (6). The list of the PDO/SDO will be loaded with the actual values.

See real-time data

Now, the drive data is accessible through and in the ctrlX Datalayer of the ctrlX CORE.

Support

Synapticon Support

support@synapticon.com 1)

Note: On our website you can reach out to our support team and have access to our documentation.

By sending an email a ticket will be created automatically. No need to register an account to talk to us.

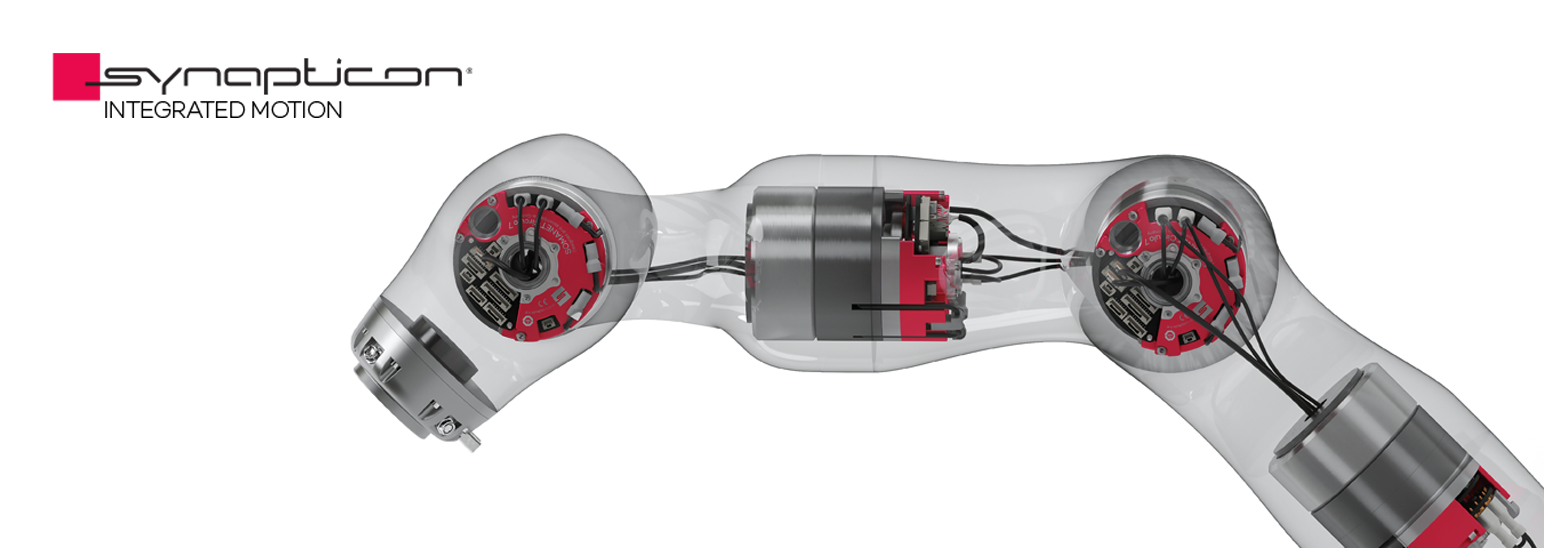

The Company

Synapticon is reshaping the world of motion control for robotics and machinery at the point of motion. We are introducing an entirely new approach to motion axes by integrating formerly discrete components, such as servo drives, sensors, brakes and functional safety into seamless units to fit integrated motors and gearmotors. We are digitalizing performance and quality factors that are so far dependent on costly electromechanical and mechanical manufacturing. Together, these innovations disrupt the point of motion as we know it today, for good.

1) Note on data protection

The email is sent directly to the partner company! This company is responsible for the processing of the data contained. Please read their data protection information before sending this email! Bosch Rexroth is not responsible for the use of the partner company's support.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.