FORUM CTRLX AUTOMATION

ctrlX World Partner Apps for ctrlX AUTOMATION

Dear Community User! We have started the migration process.

This community is now in READ ONLY mode.

Read more: Important

information on the platform change.

- ctrlX AUTOMATION Community

- Forum ctrlX AUTOMATION

- ctrlX CORE

- drive with integrated CORE used for control in existing CORE system and stand-alone system

drive with integrated CORE used for control in existing CORE system and stand-alone system

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-21-2023 03:37 PM

Hello Reader,

Hope this is the right topic to ask this question. We want to realize an application and I'm looking for a way or solution to realize this.

We have an existing unwinding machine with motion in which a ctrlX CORE runs and controls 2 axes.

Now we want to attach an extra winding machine to the machine to get the cable from the existing machine. The extra machine must be able to run in controlled torque control and thus be controlled by the CORE of the existing machine.

We also want to use the extra machine as a stand-alone machine. For this purpose we use a Drive with integrated core (XCS2-W0023ARN-2AX3T0NNET-S03RSN0NNN0NN).

So the new winding machine should be able to receive commands from the already existing system. But also be able to be disconnected and then work stand-alone via input in the drive.

Is there a function for realizing this or what approach route could I take to realize this?

Kind regards

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-23-2023 10:03 AM - edited 11-23-2023 10:03 AM

In general you can use different Ethernet based protocols for exchanging data/commands between the two controls.

Easiest way in my opinion is to use an remote data layer connection (see online documentation) and check on both sides if connection is established e.g. with a heartbeat variable. If so data/commands of this interface are used, if not they are running standalone. See also how to "Data exchange between controls C2C – ctrlX Data Layer Remote Connection"

See also the how to collection for other possibilities of data exchange. E.g. "Control to Control Communication (C2C) - Overview".

Some more general communication information see "Communicate between a ctrlX COREvirtual and other applications".

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-29-2023 12:12 PM

Check this about the different communication options: Control to Control Communication - Overview (boschrexroth.com)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-07-2023 10:52 AM - edited 12-07-2023 11:16 AM

I followed the basic step of the HowTo "Data exchange between controls – ctrlX Data Layer Remote Connection", see attachment. On the control were I want to read a remote Data Layer I setup the name of the other control user + login data + Ip adress but i wont get teh same result as the HowTo. Is there something missing?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-07-2023 11:07 AM - edited 12-07-2023 11:08 AM

Two things:

Please check what you are sending in the instruction as you added some additional "<>" to your input.

If you black out your IPv4, what could be used several times around the planet, you should also black out the IPv6 as this (normally) should be quite unique for your device.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-07-2023 11:26 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-07-2023 11:37 AM

So what is your exact current topology? Are the controls connected and in the same subnet? Are the IPs fitting?

In short are the control even able to reach each other via network?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-07-2023 11:48 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-07-2023 01:44 PM - edited 12-07-2023 02:10 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-12-2023 09:59 AM

Toplogy of the controls is as a bus. Both of them are connected to the same network in the same IP range and subnet mask. They can reach each other over the network. Confirmed via ping FB in de PLC application.

When I enable "make errors visable in tree view" I get one error? But seems like al nodes have same kind of error, is this a problem?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

12-20-2023 02:52 PM

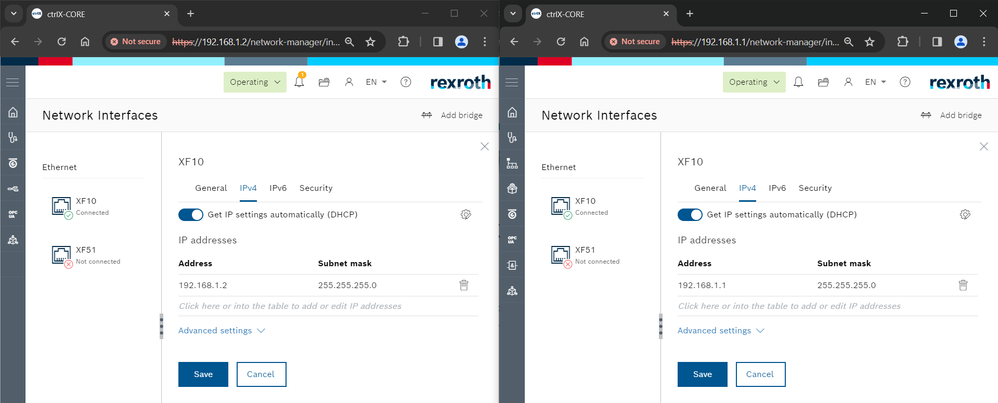

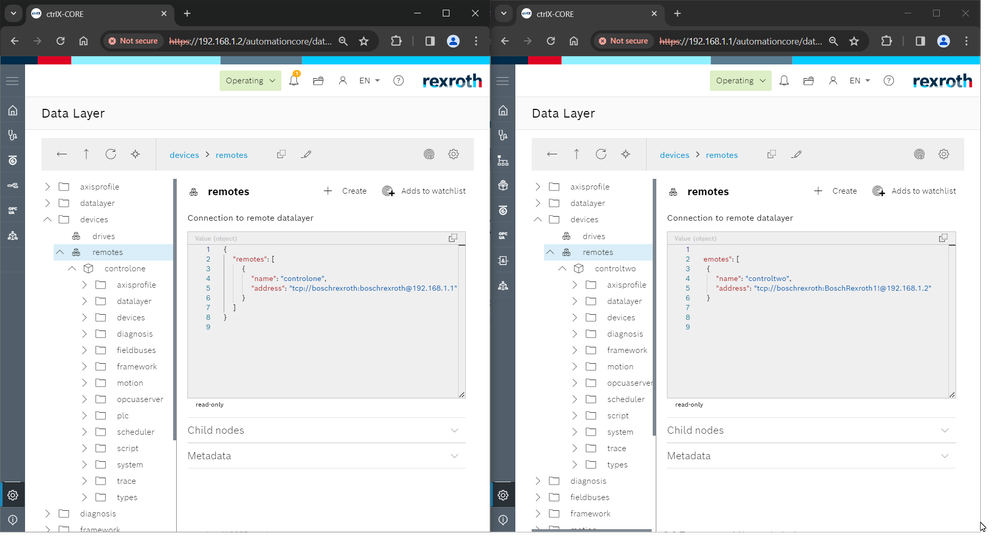

Like you said there is quite nothing to do wrong. I just prepared the topology like used in the how to mentioned above.

I connected to a switch:

- port XF10 of a ctrlX CORE one using IP 192.168.1.1 (system version 1.20.5)

- port XF10 of a ctrlX CORE two using IP 192.168.1.2 (system version 1.20.5)

- and my network port of my PC using IP 192.168.1.87 (Windows 10)

Afterwards I entered the control as remote device to each other and communication was immediately working:

Without having some information about your setup and corresponding IP settings it is just guessing what could be wrong. Are there more devices using the same IP in your network? Are your controls connected to bigger company network with a bigger network architecture? Which system apps versions are you using on each control? Are you using correct username and password?